Materials and tools

- Yarn – 2 ply Sufflandic (Suffolk/Icelandic sheep cross) natural wool, commercially spun

- Indigo Dye vat (Gulf Wars dye tent)

- Floor Loom – 4 Shaft, 6 Treadle jack loom

- Warping frame

- Boat shuttle and bobbin

- Bobbin winder

Loom

The loom that I have at home is a 45” wide, four shaft, six treadle jack loom – meaning that when I press the treadles down, specific shafts are raised into the air to create the shed needed to pass the shuttle through. I restored the loom from a slightly dusty, very rusty piece of 1970s Craft Room chic and was luckily able to source parts from the manufacturer. It’s still a little creaky and could definitely use a once over with loom wax, but it is functioning very well for its age.

In period, horizontal floor looms did exist. Starting in the 11th century, horizontal tensioned looms like the below treadled counterbalance loom began to replace the vertical warp weighted and rigid heddle looms due to their ability to efficiently produce more complex kinds of fabric. (Crowfoot, Pritchard, & Staniland, 2001) A counterbalance creates a shed by using a pulley attached to a treadle, which when pressed lifts a set of shafts into the air while simultaneously lowering the other set to create the shed.

Wool

When deciding on this project, I knew I wanted a natural wool that was both easy to work with and cost effective. Luckily, a friend in the SCA had a few cones of yarn left from her sister’s sheep, and I was able to procure enough from her to complete my project. The wool is a two ply, commercially spun from Sufflandic sheep, takes dyes well, and shows excellent definition in the pattern.

I knew that to make the weaving patterns stand out, I was going to need to take some of the wool and dye it another color to provide a contrast from the warp threads. I measured out just over 3oz of yarn and wound it up to take to Gulf Wars with me. Luckily, the Gulf Wars dye tent was doing a series of classes on Indigo vats, and I was able to use their pot to color the wool a very pretty shade of blue. Because I was doing this in a classroom setting, I was only able to dip the yarn once, leaving some small areas of dye inconsistency – which I actually kind of like for my own purposes. Ideally the dyed yarn would be a solid, even color.

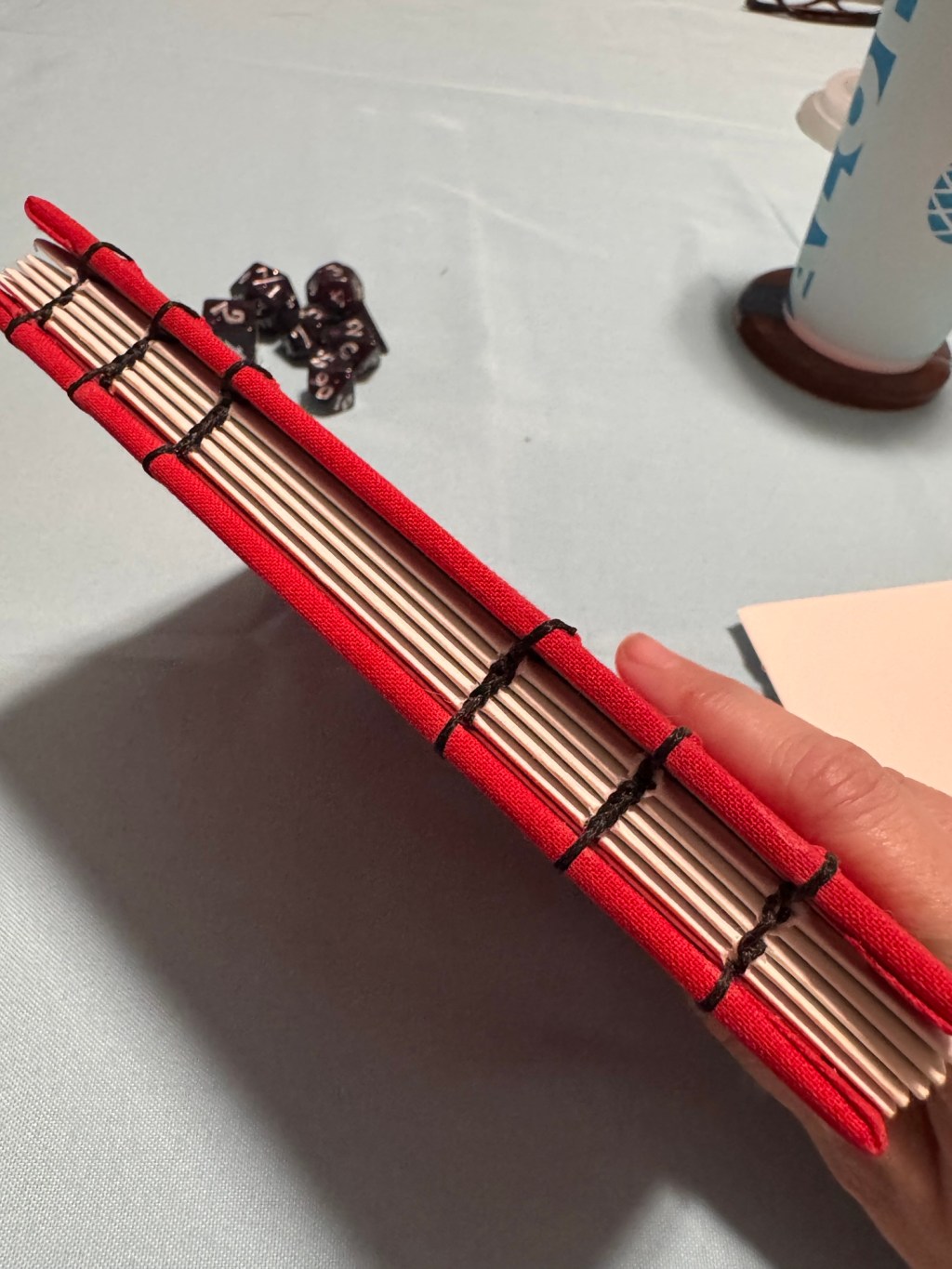

For the warp, I determined that I wanted the sampler to be about 24” wide, and that I wanted to use my 15 epi (ends per inch) reed. My warping frame measures about 4.5 yards of yarn, and I calculated that I needed to measure out 362 ends (or pieces of yarn) to get close to the result I desired – 24” wide x 15 epi = 360 ends; and because I wanted to use a floating selvedge to help make the edges neater, I added two more ends – one for each side. (Dixon, 2007)

Weaving Structures

There are endless amounts of patterns that can be done on a four-shaft loom, however I wanted to focus on structures (patterns) that were found most frequently from period and could be completed utilizing the same warp threading by simply changing the treadle tie ups.

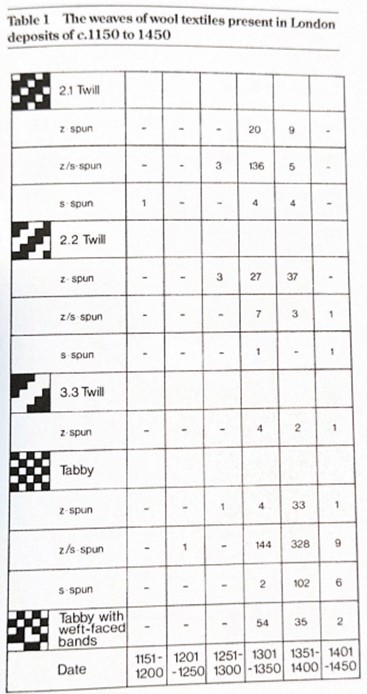

Luckily, we have plenty of extant finds showing different weaving structures, and the London Museum created a statistical frequency table, showing how often they ran into each type of pattern at dig sites in London (See Appendix A). (Crowfoot, Pritchard, & Staniland, 2001) I started planning out my project with that table, and thankfully most of the more popular patterns were all done with the same warp threading and a small change in how the treadles were tied up. What follows are examples of the weaving structures that I completed.

Tabby/Plain weave

The most popular pattern is tabby or plain weave, which is definitely easy to understand because it is a pattern that could be easily completed with a horizontal loom, a warp weighted loom, or a rigid heddle loom, making it very easy to create with tools that the weaver might have at the time.

2/2 Twill

This style of twill that has been around since the Roman Empire and made up about 80% of finds from the Viking Age. (Ostergaard, 2018) The patterned texture provided a more dense fabric than the tabby weave.

2/2 Twill Herringbone

This is a variation on the plain 2/2 twill weave, providing additional visual interest while still using the exact same warp threading and treadle tie ups. Herringbone is a pattern that dates back to the Roman Empire, and can be seen in fabrics, architecture, and jewelry. (Fulbright, 2010)

3/1 Twill

This pattern shows a design that has the blue weft thread going over three warp strands, and under a fourth, creating something similar to 2/2 twill, but providing a different take on the pattern. This version is actually used still today to make denim.

Lessons Learned

This was the third large format piece that I’ve ever woven, and I learned a lot trying to design this sampler using research and patterns to fit my purposes. It was interesting to learn that while weaving has changed, it hasn’t changed so significantly from period that we can’t recreate extant pieces and patterns using modern (or slightly more modern) equipment. The first thing that I learned is that I need to be more precise with my measurements – I wound up with an abundance of warp and not nearly enough dyed weft yarn to fill it all. The next time I design a project, I’ll be much more thorough when calculating how much I need of the weft yarn for the warp I’ve measured.

The second thing that I would do is to make sure that I do not lose my porrey cross – the strands became very tangled and by the time I had gotten them sorted out I was very tired and made a few threading errors. Since the threading errors did not affect the overall visibility of the patterns I was trying to achieve, I opted to leave them rather than to take the warp apart and do it over. Especially with the time constraints I was dealing with.

The final thing that I would do differently, is a problem that I am still learning to overcome – my draw on the edges is still fairly tight and uneven. The floating selvedges that I used helped some, but it is still something that I need to work on as I progress in learning how to weave on a floor loom.

Works Cited

Crowfoot, E., Pritchard, F., & Staniland, K. (2001). Textiles and Clothing 1150-1450. London: The Boydell Press.

Dixon, A. (2007). The Handweaver’s Pattern Directory. London: Quarto Publishing.

Fulbright, D. (2010). Akeldama repudiation of Turin Shroud omits evidence from the Judean Desert. In I. P. Lazzaro (Ed.), Proceedings of the International Workshop on the Scientific Approach to the Acheiropoietos Images. Frascati: ENEA.

Ostergaard, E. (2018). Woven into the Earth. Denmark: Aarus University Press.

Appendix A

Leave a comment